The client, a national manufacturing firm, overcame operational inefficiencies with Exent’s guidance in implementing a modern SaaS Tier 1 ERP system. The project achieved streamlined processes, enhanced control, and scalability, leading to a 3.6-year payback period. Key outcomes include real-time insights, improved security, and long-term product support.

CHALLENGE

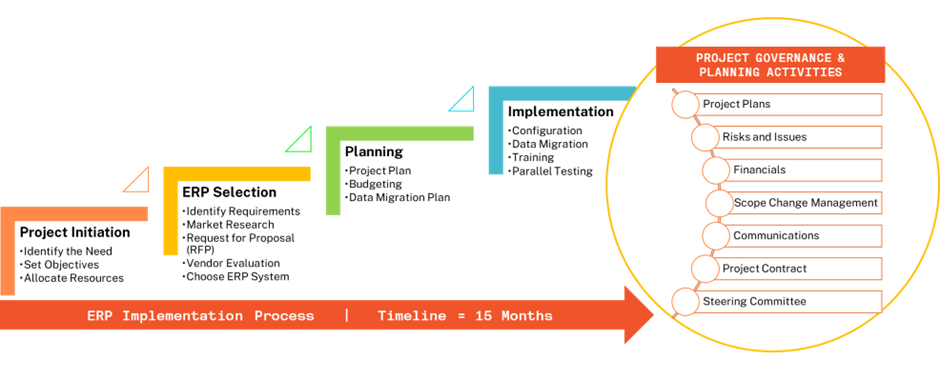

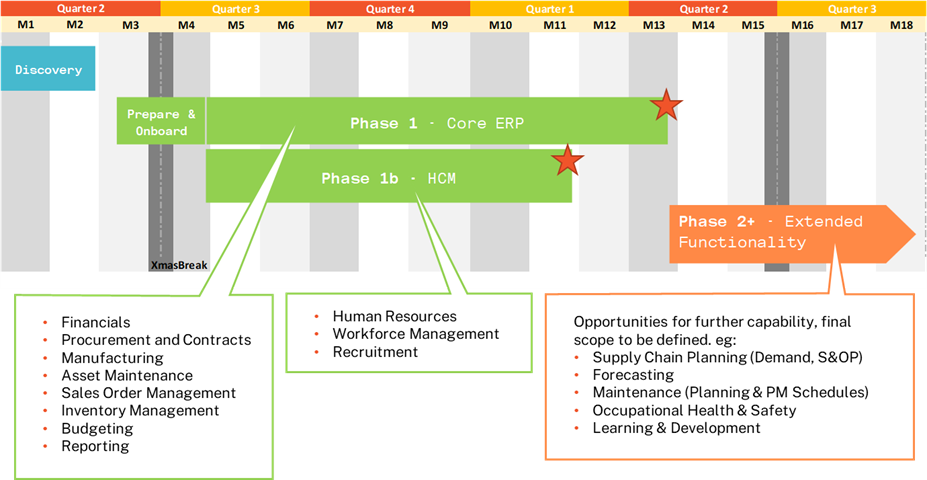

The client, a national vertically integrated manufacturer, had grown significantly over time and was experiencing inefficiencies in a number of legacy systems and processes. These challenges prompted the implementation of a modern SaaS Tier 1 Enterprise Resource Planning (ERP) system to align their operations with their growth objectives.

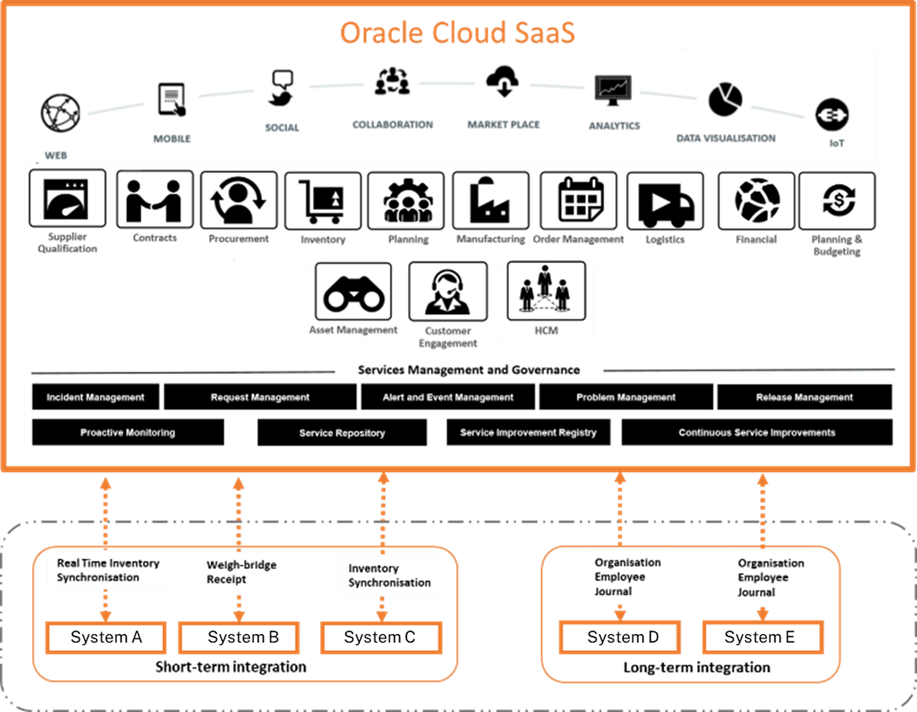

The client understood the nature of the transformative journey ahead, recognising the necessary change and major realignments to business operations, key processes and governance. The major efficiency challenges being addressed stemmed from eleven distinct legacy systems, no longer fit for purpose and very poorly integrated, further challenged by processes that were no longer adequate to future business scale.

The primary objective for the client was to sustain growth and expand into new and existing markets, particularly international markets. To achieve this, they required a modern cloud solution from a tier 1 provider.

The ERP implementation facilitated the resolution of existing system deficiencies, unification of fragmented systems, enhanced control and automation, scalability for growth, and the acquisition of deeper insights and analytics capabilities.