The daily lives of a corporate workforce are dominated by digital interactions. Entire supply chains are executed completely on computer, replacing the paper-based and physical processes of earlier years. We can apply the same lessons from Lean in traditional physical contexts – where every physical action was optimised. In the digital world, every click and keystroke can be optimised for efficiency. In this article we explore the foundations of Lean Motion Waste and share Exent’s perspectives as Lean specialists, in how we can use old approaches to solve new problems – where every click, swipe, or tap represents an opportunity to streamline.

Lean & Waste

Lean is a global better practice aimed at reducing waste and inefficiency, creating flow and throughput, and achieving standardisation and consistency across a value stream that delivers the right product or service to the right customer, in the right way, every time. It is often applied as a companion method to Six Sigma, which focuses on quality in a value stream, and when combined we often refer to the single joint method as Lean Six Sigma.

A major focus of Lean is waste reduction, which has been traditionally linked to physical movements on manufacturing floors given Lean’s origins in manufacturing. Lean Motion Waste now has new significance in the digital world. Waste can relate to an extra click to complete an online transaction, a complex website navigation, or a form that asks for redundant information. These actions don’t add value to the user experience or the operational process, and as such, they are seen as waste.

The Seven Wastes

In the world of Lean, there are “seven wastes” – a list that outlines the various forms that inefficiency can suboptimise a process or value stream. These are typically applied in a production context, but each have a specific equivalence in the digital or transactional world.

Defects

Errors or faults in products or services that require correction or rework. Eliminating defects reduces waste associated with correcting mistakes and improves customer satisfaction.

Overproduction

Producing more products or services than needed, leading to excess inventory. This type of waste ties up resources and capital unnecessarily and can result in additional costs for storage and management.

Transportation

Unnecessary movement of products, materials, or information between processes. This can increase the risk of damage, delay, and costs, and does not add value to the product or service.

Waiting

Idle time that occurs when resources are not being used efficiently, such as waiting for materials, information, or equipment. This waste results in longer lead times and decreased productivity.

Inventory

Excess products or materials that are not being processed. While some inventory is necessary, too much can lead to increased costs, storage issues, and potential wastage due to obsolescence.

Motion

Unnecessary movements by people within a process, which can lead to inefficiencies and increased risk of injury. Streamlining motion reduces time and improves safety.

Processing

Over-processing or adding more value to a product or service than customers require. This waste occurs when resources are used to create features or elements that are not valued by the customer.

Digital Process Waste

Each click represents a moment of a user’s time, a slice of their cognitive energy, and a step in their journey with a digital process. Whether navigating a website, interacting with an application, or completing an online transaction, every click matters. Recognising this is crucial for creating smooth user experiences and achieving operational efficiency.

When we speak of Lean Motion Waste in technology, we’re referring to any digital action that doesn’t contribute value to the user or the process. This could be a redundant click that could have been avoided with a more intuitive design, a complex navigation pathway that hinders rather than aids discovery, or excessive form fields that demand more information than necessary.

Take, for instance, an e-commerce site. If users have to click multiple times to add an item to their cart, navigate back to the product page, and click again to checkout, these are potential areas of Lean Motion Waste. By streamlining this process, perhaps by adding a ‘buy now’ button or providing a sidebar cart that updates in real time, you can reduce waste, improve user experience, and potentially increase sales.

Digital Lean Motion Waste also extends to operational processes. For example, businesses often maintain vast online document inventories. If employees have to click through multiple folders or use complex search functions to find a specific document, this is wasted motion. Implementing a more efficient document management system can save countless clicks and significant time.

Strategies & Tools

While a complete treatment of all lean tools and responses to digital waste would be exhaustive, here we list approaches that set the foundations for an approach to reducing and removing Lean Motion Waste in a digital context. To be clear, addressing Lean Motion Waste requires a strategic approach that is broader than a single task or activity. Best practice in implementing Lean looks at end-to-end approaches in streamlining processes, enhancing efficiency, and improving the overall user experience. Some tools that organisations might explore at the start of their lean journey include the following.

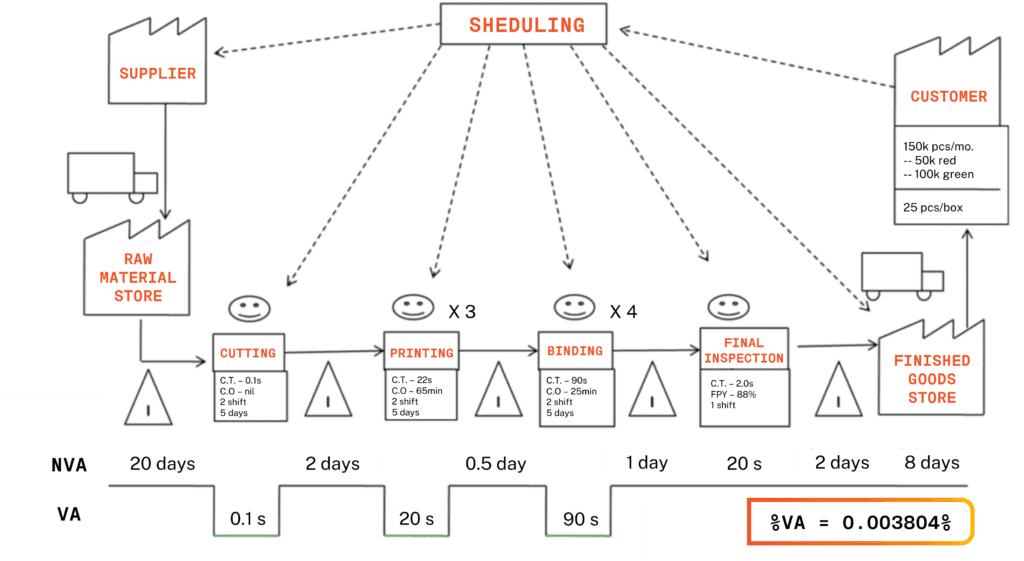

Value Stream Mapping

Use this technique to analyse your digital processes with a different approach to modelling and exploring the end-to-end creation of value. VSM can highlight areas value-adding vs non-value-adding tasks, where unnecessary clicks or steps occur, providing a clear roadmap for improvement.

User Feedback and Observation

Engage with your users. Conduct surveys, usability testing, and observation sessions to identify pain points and unnecessary motions. These insights can be invaluable for enhancing the user journey.

Data-driven Decision Making

Use data analytics and the metrics around flow, takt time (drumbeat of a consistent process) and bottlenecks to track user interactions and transactional efficiency. This can provide actionable insights to streamline or eliminate wasteful motions, making your processes more efficient.

Automation of Repetitive Tasks

Look for opportunities to automate. Recent innovations in RPA and IPA are great methods to build agile automation into digital processes. Automation can minimise unnecessary motions and boost overall efficiency if certain tasks are repetitive and don’t require human judgment.

Simplify User Interfaces

Rethink your designs. Redesign interfaces to reduce the number of clicks or steps required for common actions. A simple, intuitive interface can significantly improve the user experience.

Continuous Improvement

Lean is huge on continuous improvement by those involved in the process. Regularly review your processes, seek user feedback, and implement small, incremental changes to boost efficiency over time.

Lean Training and Awareness

Educate your team to look with new eyes, continuously generate ideas and implement incrementally – the so-called “100 1% improvements”. Training sessions on Lean concepts and methodologies can empower your team to identify and address Lean Motion Waste in their daily work.

Engage Lean Experts

Consider partnering with Lean experts like Exent to help train, launch or accelerate journeys in Lean. The additional guidance, expertise and road-tested tools support implementation and better outcomes from lean adoption.

Final Thoughts

Recognising the implications of Lean Motion Waste is crucial. Every click matters — not just in terms of user satisfaction but also in operational efficiency. By understanding and addressing Lean Motion Waste, you can make every click count, enhancing user satisfaction and operational efficiency. After all, in today’s fast-paced digital environment, efficiency is not just about speed but also about the effectiveness of each interaction. And that’s why every click matters.